An ice cream with a science topping

The scientific basis of artisanal ice cream production

Legend has it that artisan ice cream was randomly created by Mongolian horsemen while they were transporting cream across the Gobi Desert. The low temperatures this food was exposed to, together with the horses’ continuous shaking, broke the ice crystals formed in it, resulting in a soft-textured dairy product: ice cream. From Asia, it would be imported to Italy by Marco Polo in one of his many trips, and from there, it spread throughout Europe.

In Spain, ice cream tradition is linked to the towns of Xixona (Jijona) and Ibi. During the winter months, the inhabitants of these two towns collected snow and stored it in the so-called pous de neu (snow wells). In summer, they prepared ice cream by adding the juice of sweetened citrus fruits to the snow and then they got preparations such as aiguaneu (slush), arrop amb neu (grape syrup with snow), or neu amb sucre i taronja (snow with sugar and orange). Initially, they sold their ice creams in nearby cities (Alacant, Elx, etc.), from where they spread all over Spain. In fact, a very high percentage of artisan ice cream parlours in Spain were opened by families of ice cream and tigernut milk makers from Xixona and Ibi. Up to slightly over a decade ago, most artisan ice cream parlours continued preparing the same ice cream menu and following the same recipes that they were left by their ancestors.

«Artisanal ice-cream production is the result of the balanced contribution of many fields of science»

As Luis Concepción explains in Fundamentos científicos de la heladería (Concepción, 2017), most of these ice cream parlours are seasonal business models focused on impulse purchase, working long hours trying to cope with a very high and intense demand. Therefore, any small deviation in the breakneck production of ice cream, any experimenting or innovation attempt can become a real frivolity during the summer months. Now, however, perhaps due to the need to add value to the sector – following the footsteps of restaurant or pastry-making industries –, artisan ice cream makers are aware of the need to innovate in order to improve their product and to offer appealing alternatives to those presented by their competitors. But innovation requires multidisciplinary training, which is one of the main concerns of the current professionals of this sector.

The evolution of the ice cream industry is closely related to the evolution of refrigeration technology. Thus, professor Gras (2017) defines the following stages in ice cream making: 1) cooling with snow or ice, 2) cooling with refrigerant mixtures prepared by dissolving salts, 3) invention of the ice cream machine, and 4) development of mechanical refrigeration. It is important that the artisan ice cream maker knows about cooling sources and their foundations to use them ore efficiently, as well as using the most appropriate one for a specific manufacture.

However, refrigeration technology is not the only field of knowledge that artisan ice cream makers need to master. To innovate and improve the product, ice cream masters must recognise that artisan ice cream craft, as other fields of gastronomy, is not only an art. In fact, it is all science or, more precisely, the result of the balanced contribution of many fields of science. Therefore, for full professional development, artisan ice cream production requires in-depth knowledge in food science, mathematics, chemistry, physics, or nutrition.

Mathematics in artisan ice cream making

In Spain, in recent decades, the figure of the expert in formulation has emerged as a result of a historic deficit in the field of training. These experts use different formulation systems and have even promoted their own computer programs for calculation of recipes. The purpose is to rationalise what hitherto constituted an intuitive process of mixture of ingredients and to make it universal with the help of mathematics. This process involves taking several aspects into account at the same time.

«The extremely complex nature of the ingredients used in the preparation of ice cream results in a multitude of interactions between its different components»

First, the composition of the product must comply with law regulations. There are significant differences depending on the type of ice cream that one wants to produce. Thus, for hard ice cream, Spanish legislation dictates a minimum of 8% of milk fat and a minimum of 2.5% of milk proteins. Conversely, if it is a milk-based ice cream, these minimums are reduced to 2.5% of milk fat and 6% of non-fat milk dry matter. To achieve these rates, it is absolutely necessary to take into account the partial contributions of the different ingredients to the final formula of the product and its characteristics (that is, to its composition).

Second, the freezing temperature of the mixture must be under control. In this sense, it is important to keep in mind that the incorporation of components involves a change in the freezing temperature of the mixture. This will be more or less pronounced depending on the composition of the ingredients used. Thus, for example, we can indicate that the substitution of sucrose for dextrose in the mix almost doubles the capacity to reduce its freezing temperature.

Finally, another aspect that can be mathematically adjusted is the sweetness of the product, taking into account the relative sweetening powers of the ingredients. By doing so, it is possible to standardise this organoleptic property traditionally linked to one of the typical ingredients of this product: sugar.

The chemistry of ice cream

Knowing the composition of the ingredients used in the production of ice cream, as well as the changes that these components undergo during the production and storage of the final product, is part of what is known as «food chemistry applied to ice cream» or what might also be called «ice cream chemistry» (Goff, & Hartel, 2013). The extremely complex nature of the ingredients used in the preparation of ice cream results in a multitude of interactions (chemical reactions) between its different components. Sometimes these interactions are desired and may be useful for some purpose, but others are undesirable or harmful because they reduce the organoleptic value of the final product. These interactions between the ingredients’ components are controlled by many parameters or variables. Only by knowing and understanding their action will we be able to control them and use them properly to get a better quality and more stable product until the moment it is consumed.

Thus, the most basic or traditional aspects of ice cream chemistry allow, for example, to control the precipitation of lactose (and thus prevent the emergence of the sandy texture characteristic of some low-quality ice cream); or to reduce and slow down the oxidation processes of unsaturated fatty acids which, especially in formulations that contain dried fruit, can have significant presence. On the other hand, by controlling the possible chemical reactions between its components, it is also possible to prepare ice cream with particular properties, and thus to stand out from our competitors. Some examples of ice cream innovation developed in recent years, which has given rise to interesting products, including fluorescent ice cream that glows in the dark due to the incorporation of jellyfish proteins, and ice cream that changes colour due to the presence of substances that modify their colour depending on the environment’s pH (for example, in contact with saliva).

«Innovation in ice cream production requires multidisciplinary training»

It is important to finish this section by mentioning the so-called «chemo-phobia» that prevails in some population groups and that often receives excessive media attention, usually with no grounds (Entine, 2011). Despite the fact that chemistry is part of ice cream’s own nature, and that it is not possible to dispense with the advantages for artisanal ice cream making of the use and control of the components which give rise to the desired reaction, the consumers’ reaction towards «chemistry» tends to be negative. Ice cream masters must be informed about the toxicological aspects of each of the ingredients used in the craft of the product in order to make a responsible use and be in accordance with legislation. Only then can they deal with and defend the quality of their product.

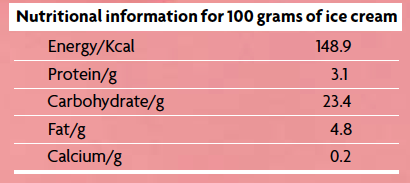

This chart shows the average nutritional composition of milk-based ice cream on 100 grams of product. Contrary to widespread belief, ice cream can be considered food with average energy content, although it is important to keep in mind the high amount of sugar that is often added. / Source: J. Mora and S. Maestre

Ice cream and the science of nutrition

Another scientific field that ice cream masters must be aware of is the one concerning nutrition, inasmuch as their product is food. Ice cream provides nutrients and energy, thus covering our physiological needs, but it also plays a very important psychological role due to its organoleptic characteristics and the fact that it is associated with leisure moments. It is impossible to establish criteria that is common to all ice cream, since, from the nutritional point of view, a milk-based ice cream is not the same as a sorbet. Even within the same ice cream category, the nutritional value will depend on the ingredients used to prepare them (Vidal, 2005): amount of water, milk (whole or skim), fats, carbohydrates, dried fruits, fruits, eggs, etc. This makes ice cream more than just sugar. It is suitable for any age and can and must be compatible with any type of well-balanced diet.

«The evolution of the ice cream industry is closely related to the evolution of refrigeration technology»

Contrary to widespread belief, the average caloric value of an ice cream ranges between the 110 Kcal of milk-based ice cream to the 250 Kcal of hard ice cream, so it can be considered to have average energy content. The protein value and the fat and calcium content of milk-based ice creams is similar to the milk used to make them. It is important to take into account the high contribution of total carbohydrates that tend to be added to the product.

Another increasingly-requested aspect is the production of artisan ice cream aimed at people with special diet needs. This involves making ice cream fit for consumption by people with diabetes (Soukoulis, Fisk, & Bohn, 2014), coeliac diseases, or allergies. In this field, knowledge of nutrition requires significant interaction with chemistry, since it is necessary to make the appropriate modifications in the composition of ice cream to make it suitable for groups of people with specific needs. Thus, for example, to make lactose-free ice cream, it is possible to operate in two ways: hydrolysing the disaccharide with the help of lactase, or by replacing milk protein with a vegetable-based protein (soy or other leguminous plants), which would also meet the demands of vegetarians. The previous characterisation of the properties of these substances is key to incorporate them into the formulation of the product. Finally, it is worth mentioning that, due to its nature, basically its structure, and the fact that the processing and the storage take place at low temperatures, ice cream becomes a promising product to act as a vehicle for bioactive compounds and microorganisms beneficial for our health (Whelan, Vega, Kerry, & Goff, 2008).

The physics behind ice cream making

While the mental link between food and chemistry is often loaded with negative hints, the binomial of physics and food is often surprising for the general public, because it is unexpected. Food, products that are inserted into the mouth and processed to be subsequently swallowed, seem to be light-years away from the complex physical systems that we usually have in mind and which also need complex methods and instruments to be studied. However, it is necessary to add value to the contribution of different aspects related to physics, the so-called «soft matter physics» (Vilgis, 2015), to the characteristics of food in general and of ice cream in particular. These aspects include the mechanical properties and the structure of the product. Ice cream is analysed organoleptically in our mouth, where we characterise its texture (by breaking its structure) and its flavour and aroma (when released the sapid and the volatile substances it contained).

In ice cream we can find immiscible components such as water, air, and lipids in liquid or solid stage. Therefore, ice cream is typically dominated by interfaces. Optimising the conditions for the formation and stabilisation of these interfaces becomes a key factor to achieve a product of the highest quality. For example, controlling the size of the formed ice crystals becomes essential to give the ice cream a creamy texture when they are small enough, or granulated, when they are large enough. Something similar occurs with the formation of the air-water interface: a greater incorporation of air – that is, a greater overrun, according to the jargon used by professional ice cream makers – creates warmer ice cream, whereas if the interface is not created effectively or is thwarted, the proportion of air is reduced, resulting in colder ice cream. Along these lines to understand how these interfaces behave, we find the recent development of an ice cream that includes fibres from vegetable waste from banana trees, which manages to reduce the melting speed of the ice cream and to improve also the product’s texture formulated with these substances.

Technology to innovate

As we have seen in the previous sections, the organoleptic and nutritional characteristics of ice cream are heavily dependent on the ingredients used and on the possible interactions between them. However, it is also necessary to underline the great importance that a proper production process has on the quality of the final product.

«Ice cream provides nutrients and energy, thus covering our physiological needs, but it also plays a very important psychological role»

Each one of the stages is based on operations that require special care, since they are aimed at the production of food. In addition, they involve the use of specific machinery. In this sense, it is worth to note some innovations that have achieved significant improvements in the quality of the final product; for example, the incorporation of floating-type scrapers in the batch freezers, getting a reduction of heat generated by friction during the batch freezing process, which results in a lower re-crystallisation of water and, therefore, improves the product’s organoleptic characteristics. Another advance is the design of refrigerated display cabinets with a more homogeneous distribution of temperature, which, in addition, underlines the importance of controlling the whole process, including the service.

It is vital for ice cream masters to know the basis of each of the stages of the process, the machinery used, and the possibilities offered by the market. Only in this way they can choose the most suitable technological process to make the traditional products and be able to innovate preparing new ones.

Ice cream production stages. Ice cream masters must know each stage and the machinery used perfectly, as well as the possibilities offered by the market. Only in this way they can choose the most suitable technological process to make a traditional product and at the same time to innovate. /Source: J. Mora and S. Maestre

A multidisciplinary sector

The brief review carried out in the previous paragraphs tried to show some examples of issues in which science is or can be placed at the service of master ice cream makers. We aimed, therefore, to give clear proof of the need for the professionals in this sector to gain a multidisciplinary training that they can use as a fundamental tool in their day-to-day work. Only in this way they will be able to innovate and produce high-quality ice cream at the level the public deserves and make a difference in their product.

Concepción, L. (2017). Un recorrido por la heladería contemporánea. Países y profesionales influyentes. In J. Mora, & S. Maestre (Eds.), Fundamentos científicos de la heladería. Alacant: Publicacions Universitat d’Alacant.

Entine, J. (2011). Scared to death-how chemophobia threatens public health. New York: The American Council on Science and Health.

Goff, H. D., & Hartel, R. W. (2013). Ice cream. Boston, MA: Springer US.

Gras, L. (2017). Historia del helado. In J. Mora, & S. Maestre (Eds.), Fundamentos científicos de la heladería. Alacant: Publicacions Universitat d’Alacant.

Soukoulis, C., Fisk, I. D., & Bohn, T. (2014). Ice cream as a vehicle for incorporating health-promoting ingredients: Conceptualization and overview of quality and storage stability. Comprehensive Reviews in Food Science and Food Safety, 13(4), 627–655. doi: 10.1111/1541-4337.12083

Vidal, M. C. (2005). El libro blanco de los helados. Barcelona: Semfyc.

Vilgis, T. A. (2015). Soft matter food physics—The physics of food and cooking. Reports on Progress in Physics, 78(12), 124602. doi: 10.1088/0034- 4885/78/12/124602

Whelan, A. P., Vega, C., Kerry, J. P., & Goff, H. D. (2008). Physicochemical and sensory optimisation of a low glycemic index ice cream formulation. International Journal of Food Science